HEAT EXCHANGER GROUP

Heat Exchanger group is self-reliant to cater to the requirements of heat exchangers from process industries, railway, space, defence, thermal & Nuclear Power sector applications.

We have highly experienced team conversant with various national and international design codes, capable of in-house design, product development, testing and product validation.

Group is equipped with state-of-the-art manufacturing facilities which are capable of meeting the challenges of latest technology, conformance to product standards & delivery commitments.

PRODUCT PROFILE

| Equipment | Type of design applicable |

|---|---|

| Surface Condenser | Thermal & Mechanical |

| Moisture Separator Reheater | Thermal & Mechanical |

| High Pressure Heaters | Thermal & Mechanical |

| Low Pressure Heaters | Thermal & Mechanical |

| Drain Cooler | Thermal & Mechanical |

| Gland Steam Condenser | Thermal & Mechanical |

| Auxiliary coolers | Thermal & Mechanical |

| Nuclear Primary & secondary cycle heat exchangers | Thermal & Mechanical |

| Process Heat Exchangers | Thermal & Mechanical |

| Pressure Vessels (Primary & secondary cycle) | Mechanical |

| RE Joints | Mechanical |

| Butterfly valves | Mechanical |

ENGINEERING CAPABILITIES

- Strength calculations for nearly all components

- Finite Element Analysis

- Seismic Analysis

- Wind Analysis

- Flow-Induced Vibration Analysis

- 3-D modelling of different assemblies

- Designs developed for longer life, easy maintenance and cost reduction

- Design to International Codes and Standards

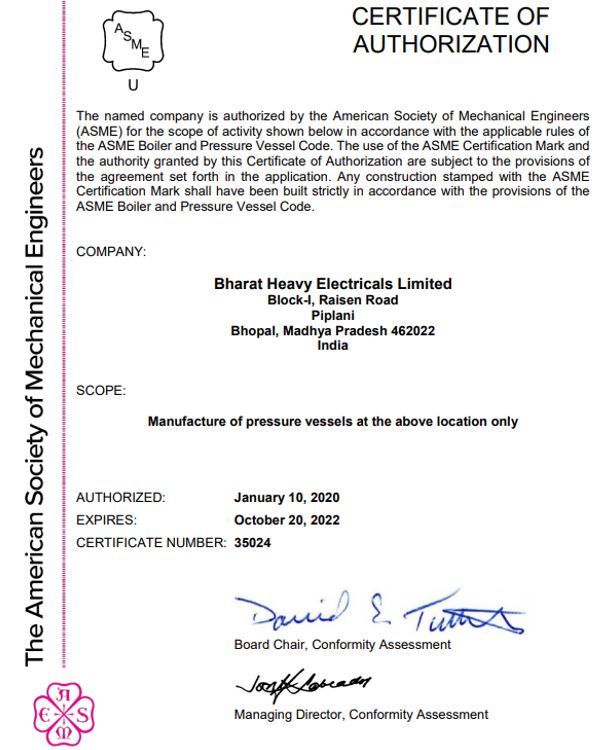

- ASME Sect. I. III & VIII

- TEMA Standards

- Indian Boiler Regulation (IBR)-1950

- IS – 2825

- P.D. – 550

- H.E.I. STANDARDS

- A.P.I.

- AD-MERKBLATT

- ASME U stamp etc.

- Member of HTRI

- Conversant with design of all type of shell & tube heat exchangers, feed water heaters, surface condensers, Gland Steam Condenser, turbine oil cooler, motor coolers, cooler for defence applications, transformer cooler, Hydro cooler, MSR, LSR, pressure vessels Nuclear primary & secondary cycle heat exchangers, butterfly valves, Rubber Expansion joints, Aux equipment etc.

MANUFACTURING FACILITIES

- CNC PAMA HORIZONTAL BORING MILLING AND DRILLING MACHINE

- CNC PAMA HORIZONTAL BORING MILLING AND DRILLING MACHINE

- 5 AXIS CNC PAMA HORIZONTAL BORING MILLING AND DRILLING MACHINE

- CNC SAFOP LATHE MACHINE

- CNC PEITRO VERTICAL TURNING & MILLING MACHINE

- WOTAN HORIZONTAL BORING MILLING AND DRILLING MACHINE

- “INNOCENTI” Milling Boring & Drilling Machine.

- DOUBLE COLUMN PLANO MILLING (HOMMA) JAPAN

- MORANDO LATHE

- CNC FLAME CUTTING MACHINE

- PLASMA CUTTING MACHINE

- THERMAL AUTOMATICALLY CONTROLLED

- STRESS RELIEVING FURNACE (FOR FULL S.R.)

- SPECIAL STRESS RELIEVING FACILITY

- (FOR PARTIAL OR LOCAL S.R.)

- CNC DEEP HOLE DRILLING MACHINE

- CNC MULTISPINDLE DRILLING MACHINE

- HIGH SPEED SINGLE SPINDLE CNC DRILLING M/C (FOR CARBIDE DELTA DRILLING)

- TUBE-TO-TUBESHEET WELDING MACHINE

- ELECTRONICALLY / HYDRAULICALLY CONTROLLED TUBE EXPANDERS

- NARROW GAP SAW WELDING MACHINE

- PORTABLE TUBE END FACING Machine

- POLYEURATHENE PAINTING BOOTH WITH OVEN

- HYDROSTATIC TESTING FACILITY

- PULSED TIG WELDING M/cs

- SYNERGIC MIG WELDING M/cs

- ELECTROSLAG WELDING M/c

- PLASMA TRANSFERRED ARC WELDING M/c

- CNC MULTISPOT / SEAM RESISTANCE WELDING M/c

- INVERTER BASED SMAW WELDING M/c

- DUST FREE ENCLOSURE FOR SPECIALISED JOBS SUCH AS NUCLEAR PRIMARY CYCLE HX,

- RADIOGRAPHY PIT

5 AXIS CNC Horizontal Boring Machine

Deep Hole Drilling

Innocenti NC Boring Machine

CNC Lathe Machine

Narrow Gap Welding

Dust Free Enclosure

Special Stress Relieving Facility

WPS AND WELDER QUALIFIED BY AGENCIES

- NPCIL

- NTPC

- PGCIL

- LLOYDS

- NAVY

- NHPC

- SJVNL

- Various other private customers

- Note: (For many customers for work inside BHEL premises WPS and Welder qualified by BHEL is acceptable)

CUSTOMERS & INSPECTION AGENCY

- ALL STATE ELECTRICITY BODIES

- OTHER PRIVATE CUSTOMERS