HYDRO TURBINES

Powering Progress

BHEL has proven expertise, technology and capability to manufacture, supply and commission Hydro Power Generating sets since more than six decades. BHEL has designed, manufactured and commissioned Hydro Generating sets ranging from unit capacity of 0.1 MW to 200 MW both in India as well as abroad. Till date, BHEL has successfully supplied and commissioned more than 550 nos. TG sets totalling to an installed capacity of more than 28,000 MW.

BHEL has augmented its installed manufacturing capacity to 2500 MW / 25 nos. TG sets per year. Apart from supplying TG sets for green-field projects, BHEL is also designing, manufacturing and supplying newly designed TG sets with uprated capacity for R&M projects both for BHEL machines as well as non-BHEL machines. BHEL is also supplying O&M spares for smooth operations of all existing power houses.

BHEL HYDRO POWER PLANT CAPABILITY

BHEL’s products & systems are technology intensive and R&D / Technology development is of strategic importance in its endeavor to become an all-inclusive engineering enterprise.

BHEL’s Hydro Manufacturing facility is fully equipped to deliver entire range of varied products for Hydro Power Plant requirements providing one-stop solution on overall basis, the scope of supplies & services majorly comprises of following products:

- Hydro Turbine-Generator Set : Custom-built conventional Hydro Turbines of Kaplan, Francis and Pelton types with matching Generators, Pump Turbines with matching Motor-Generators upto 400 MW.

- Bulb Turbines with matching Generators upto 10 MW.

- High capacity pumps along with matching motors for Lift Irrigation Schemes (upto 200 MW).

- Electro Hydraulic Microprocessor-based Digital Governor for Conventional Turbines

- Microprocessor-based Digital Controller for Lift Irrigation Schemes.

- Mini/micro Hydro sets with PLC-based compact Digital Governor

- Static Exitation Systems for Hydro Generators & Motors

- Brushless exciter for Hydro Generators & Motors

- Special purpose Motor Generators sets

- Spherical (rotary) Valves, Butterfly Valves and auxiliaries for hydro stations

- Upgradation of Hydro Machines

- Balance of Plant Packages.

MAJOR HYDRO EQUIPMENT TYPE & CAPABILITY

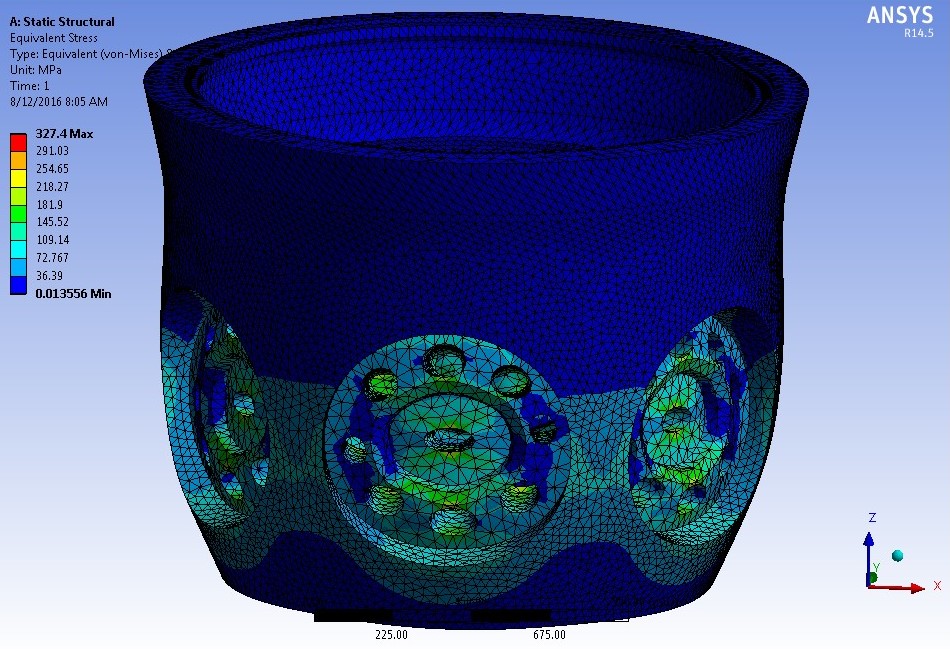

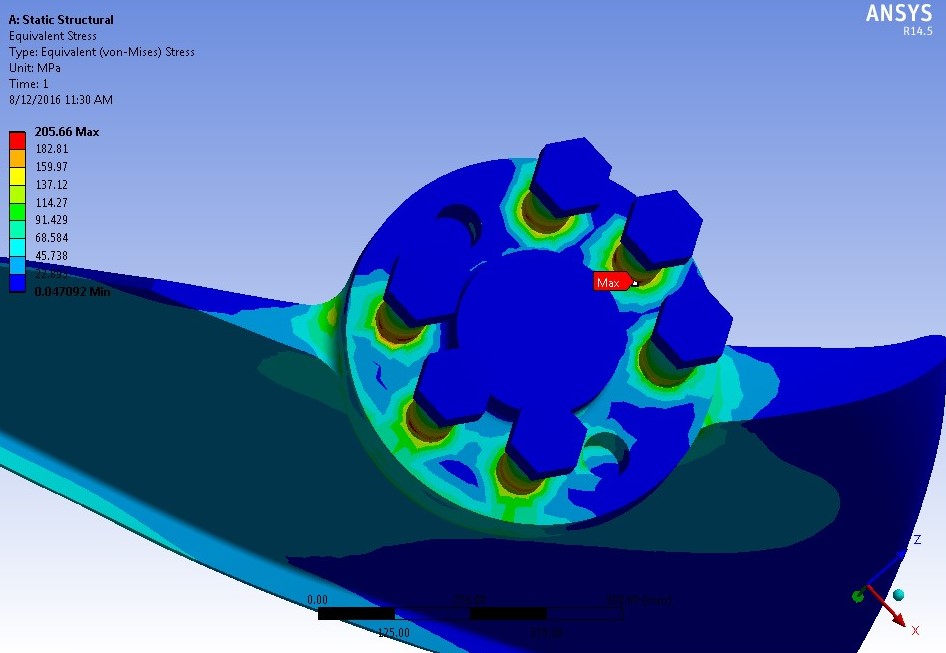

BHEL, in its perpetual endeavour towards up gradation of hydro turbines and valves has kept itself abreast with advancements in the fields of hydraulic designs, mechanical designs, techniques of stress analysis, materials, testing techniques, Governing and control philosophy etc. and has made use of the operational feedback on these products. These up gradation efforts have gone a long way towards overall product improvement in term of performance, quality, easier maintenance, economy, etc.

TURBINE & AUXILIARIES

Typically we design various types of turbines/pumps such as

- Francis Turbine - upto 400 MW

- Kaplan Turbine - upto 100 MW

- Pelton Turbine - upto 400 MW

- Lift Irrigation Pumps - upto 200 MW

- Reversible Francis Turbine - upto 300 MW

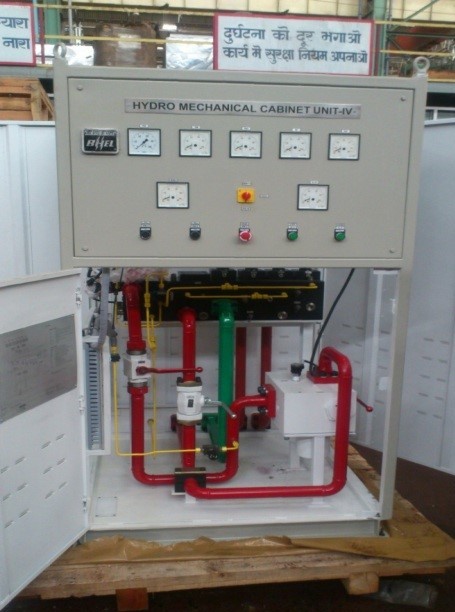

HYDRO GOVERNOR

BHEL manufactures state-of-the-art Microprocessor based Digital Governors with matching Actuator and Oil Pressure System. Digital governor is based on the DCS platform for computerized control system and hence ensures unified automation benefits. The system provides high accuracy, resolution, speed of response, design flexibility with stability of parameters. The Governor is compliant with IEC-61362 requirements. We offers Governing System for all types and ratings of Hydro Turbines.

VALVES

BHEL has vast experience in designing, manufacturing, erecting and commissioning Butterfly(1500-7000mm) and Spherical Valves(500-4000mm), to shutoff water flow in penstock as well as for use as main turbine inlet valves. We also provide pressure relief valve ,control cabinets, upstream and downstream pipes, and hydraulic servomotors for actuating the valve, counterweight arrangement, bypass systems, etc. along with our valves

We offer high capacity vertical centrifugal pumps for Lift Irrigation Schemes with end-to-end services from hydraulic design, project engineering, manufacturing to erection & commissioning. We have manufactured pumps having input power well in excess of 200 MW. We can offer pumps& Motor with or without adjustable guide apparatus as per customer’s requirements at high levels of efficiency and reliability.

BALANCE OF PLANT

A Large number of Hydro projects are being executed by BHEL many of which are on turnkey / EPC basis including many export projects.

Complete Power Plant Auxiliary System are designed keeping in view the overall project requirements. Engineering, procurement and site installations of all BOP packages of power plant is done by BHEL. The main BOP package are listed below.

- Electric Overhead Cranes

- Heating Ventilation And Air Conditioning System

- Mechanical Workshop

- Elevators

- Earthing / Grounding of Power House, etc.

- Illumination System

- Diesel Generator Sets

- Firefighting System

- Public Address System

- Security & Surveillance System

- Telephone / Communication System

- Electrical / Mechanical Workshop Equipments

- Fiber Optic Cable

- GIS and Outdoor Switchyards

- XLPE Cables

MANUFACTURING CAPABILITIES:

BHEL Bhopal has a dedicated Hydro Turbine Manufacturing Block with following state of the art machining centres

Hydro Turbine Machining Centre includes:

- Lathes

- Vertical Borers

- Horizontal Borers

- Planning Machines

- Radial Drilling Machines

- Vertical Borer

- CNC Vertical Machining Centre

- CNC Vertical Borer

- CNC Horizontal Borer

- CNC Horizontal Borer(5 axis)

- CNC Lathe

- Radial Arm Drilling Machine

Fabrication facilities include:

- Electro-Slag Welding

- TIG/MIG Welding

- Narrow Gap Welding

- 1000 Ton capacity Press

- 600 Ton Plate Bending Machine

- 3000 Ton Shell Bending Press

- Electronic Flame Cutting Machine

- Stress Relieving Furnace

- Shot Blasting Chamber

- NDT facilities like Dye-Penetrant Test, Magnetic Particle Test, Ultrasonic Test & Radiographic Test

- On-Site Fabrication facility

HVOF Coating Shop

The HVOF plant at BHEL Bhopal is the State of Art facility and one of the biggest in the world for HVOF coating. This HVOF coating facility is meant for providing hard coating on components which are subjected to abrasive erosion. Being fully automatic, integrated and robotized plant, the quality and consistency of coating is of the highest order can be achieved.

ENGINEERING CAPABILITIES

BHEL offers complete solution for hydroelectric power stations, covering the Engineering, Manufacturing, Erection and Commissioning of equipment, after sale services and spares. It undertakes the uprating, renovation and rehabilitation of old power houses.

Continuing its tradition of winning prestigious National / international awards in diverse arenas, BHEL and its employees won several awards in the area of business excellence and industry leadership , innovation , corporate social responsibility and leadership.

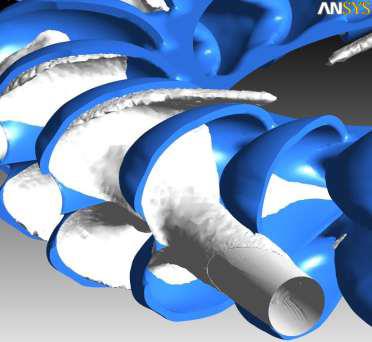

RESEARCH & DEVELOPMENT OF HYDRO TURBINES

Our dedicated team of Engineers at Bhopal Plant and Corporate R&D, Hyderabad ensure that the features of our products, processes, emerging techniques and technologies are always updated and upgraded to meeting the satisfaction and demands of Customer. This is carried out by hydraulic research of our products and their successive development by using processes like Experimental Model Testing & through various sophisticated computer programs.

CENTRE OF EXCELLENCE- HYDRO MACHINES (COE-HM), BHOPAL

COE-HM has been spearheading BHEL's quest to remain in the forefront of development of efficient Hydro turbine profiles since last two decades. COE-HM is equipped with sophisticated and modern laboratory to conduct detailed & intensive studies by Experimental Model Testing. HMDS is also accredited in accordance with ISO / IEC17025:2017 by National Accreditation Board for testing and calibration Laboratories.

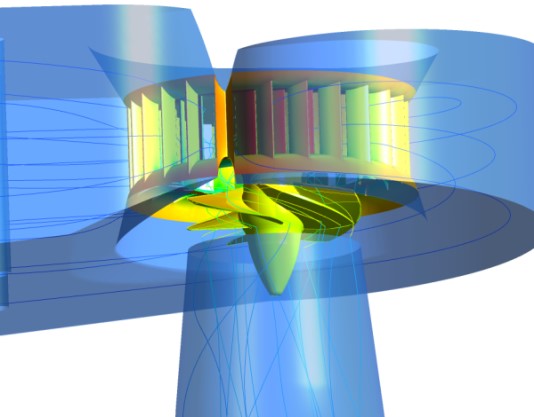

COE-HM, Bhopal is also equipped with a CFD center which forms the basic backbone of Hydraulic design and optimization of Hydraulic profiles. A wide variety of in-house developed codes and commercial CFD codes is available to enable Engineers to undertake advance research in the field of hydraulic machinery. The elaborate CAE and numerical simulation capability facilitates to enhance the micro-level understanding of hydraulic phenomenon and effect changes in the hydraulic characteristics to improve performance.

COE-HM is equipped with an in-house manufacturing facility for accurate manufacturing of Hydro turbine model components for model component machining as per tolerances of IEC 60193.

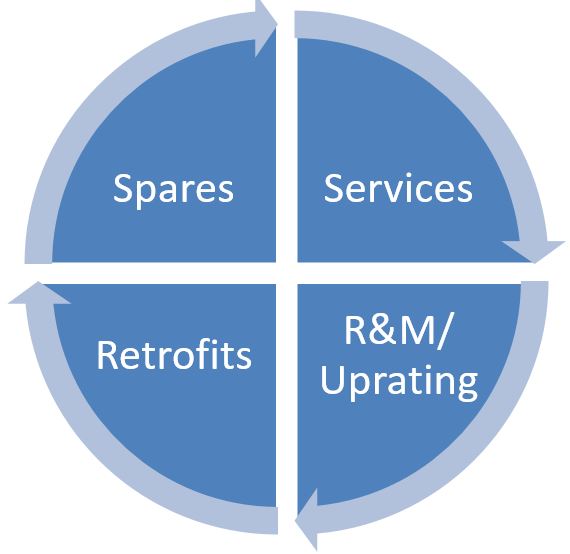

R&M and Uprating: Advantages

- Life Extension by 15-20 years beyond average life of 35 years at comparatively lower cost & lead time period.

- Restore lost capacity and/or enhance rated capacity.

- Increase in safety, reliability, availability and operational flexibility.

- Increase in generation with improved performance.

- Introduction of state-of-art systems/ technology for better O&M practices.

- Possibility of reducing cost of generation.

- Ensures safety standards upgrades.

- Up-gradation of obsolete equipments.

SPARES

Services for Hydro sets covers:

- Long Term Service Agreement (LTSA)

- MoUs with customers

- Execution of lump sum servicing jobs including Annual/Capital Overhauls for Turbine, Generator & their Auxiliaries.

- Availability of experts at site to supervise Servicing & Trouble Shooting jobs.

- Erection & Commissioning (E&C) jobs of Hydro Power Plants.