STEAM TURBINES

Product Profile

FOR COAL BASED THERMAL POWER STATIONS

- Steam Turbines for 195MW, 210 MW, 250MW, 270MW sets

- Spares for all BHEL make Steam Turbines up to 500 MW

- Repair of Steam turbine up to 500 MW

FOR NUCLEAR POWER PLANTS

- Nuclear Steam Turbine for 220 MW sets

- Nuclear Steam Turbine for 700 MW Steam Turbines sets

- Spares & Repairs of 220 MW Nuclear Steam Turbine

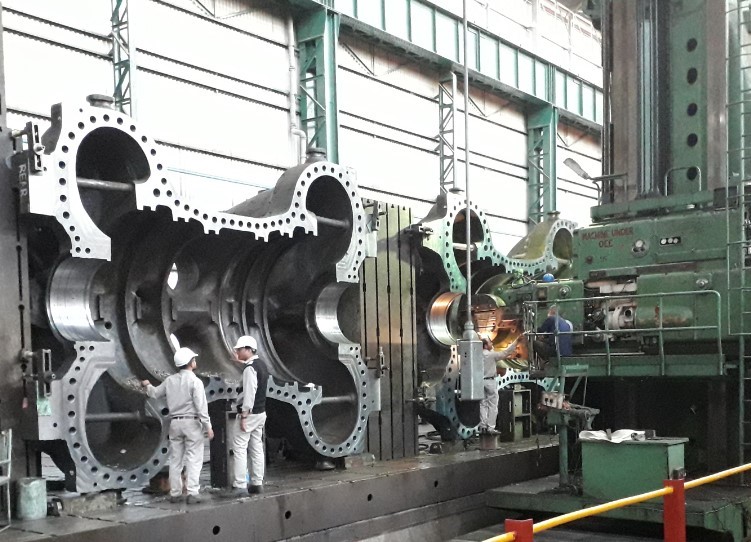

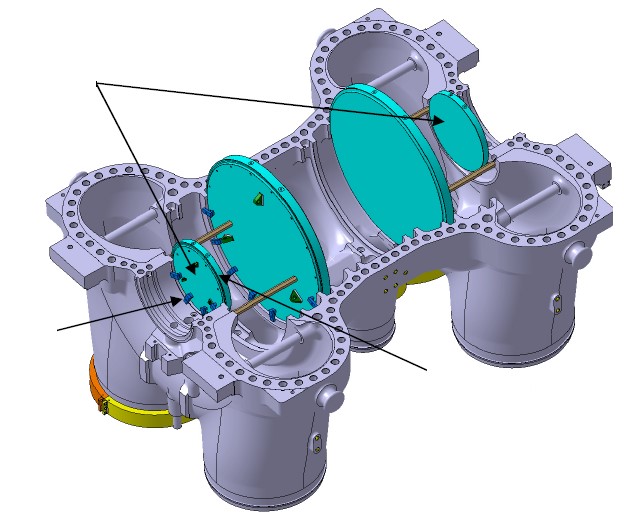

HP Casing

LP Inner Casing

MARINE PROPULSION

- Spares & Repairs for 15000 SHP MARINE Turbines.

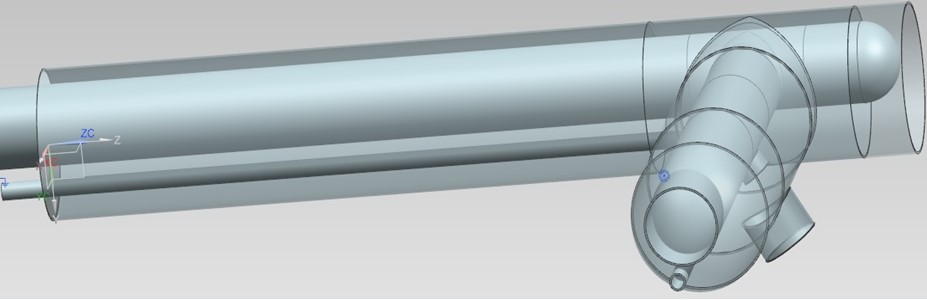

PIPING FOR 700 MW NUCLEAR STEAM TURBINE (SECONDARY CYCLE)

- Cold Reheat (CRH) / Hot Reheat (HRH) Piping

- LP Extraction Piping

- Stainless Steel Co-axial Lube oil piping (PIPE IN PIPE)

- Turbine Integral piping (Lube oil piping, Control Oil piping etc)

CRH Piping

LP Extraction Piping

Co-axial Lube oil Piping

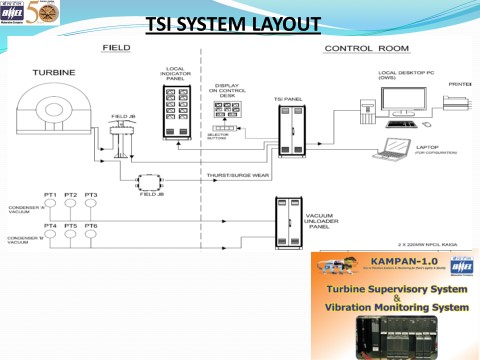

CONTROLS & INSTRUMENTATION FOR 250MW/270MW/500MW/220 MW/700MW THERMAL/NUCLEAR POWER PLANTS

-

Turbine Supervisory Instrumentation (TSI) System: For 236MW Nuclear Turbine

-

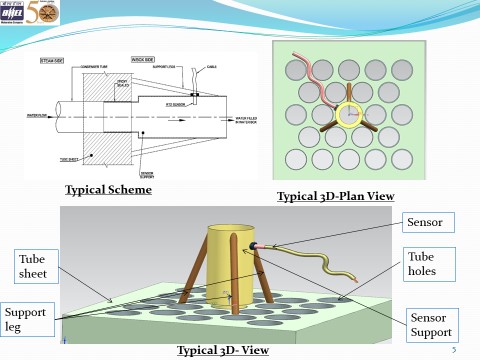

Online Fouling measurement System for Condenser Tube as per ASME PTC 12.2 for 700MW Nuclear Power Plant: Developed first time by BHEL Bhopal

-

Profibus system for 700MW Nuclear Project: First time Developed by BHEL Bhopal for Condenser & MSR Instrumentation

Salinity Measurement in Condenser for 700MW Nuclear Power Plant: First time by BHEL Bhopal

Air ingress in Condenser for 700MW Nuclear Power Plant: First time by BHEL Bhopal

Spares for C&I Items of Thermal & Nuclear Turbine

- Spares Collins Position Transmitter – used in EHC

- Speeder Gear Motors & & Load Limiting Gear Motor Used in Governing rack

- Solenoid valves

- Proportional Valves

- Position Transmitters for EHC

- Level Instruments (GWR Type Level Transmitters/ Level switch)

- High temperature instrumentation for HP Heaters

- Thermocouples up to 24 Meter length & RTD up to 30 Meter length

- New Valve Position transmitters (LVDT type)

STEAM TURBINES SUPPLY HISTORY-BHEL BHOPAL

| RATING (MW) | TYPE | NO. OF SETS SUPPLIED | FIRST SET COMMISSIONED |

|---|---|---|---|

| 1. COAL BASED THERMAL POWER STATION | |||

| 30 MW | SINGLE CYLINDER / IMPULSE | 06 | 1969 |

| 120 MW | THREE CYLINDER / IMPULSE / REHEAT | 18 | 1974 |

| 195/210/250/270 MW | THREE CYLINDER / REACTION / REHEAT | 22 | 2016/1988/2016/2014 |

| 2. NUCLEAR POWER PLANTS | |||

| 220 MW NUCLEAR | TWO CYLINDER / IMPULSE / REHEAT | 10 | 1983 |

| 700 MW NUCLEAR | 4 CYLINDER / IMPULSE / REHEAT | 04 | UNDER MFG. / ERECTION |

| 3. MARINE PROPULSION | |||

| 15000 SHP | SINGLE CYLINDER / IMPULSE / NON-REHEAT | 20 | 1974 |

ENGINEERING CAPABILITY – STEAM TURBINE

- Expertise in Repair of Siemens design modules upto 500 MW & their retrofitting to achieve their functional parameters

- Design Execution, Procurement, Manufacturing , testing and supply of Static parts for 700 MW Nuclear Steam Turbine (GE Design)

- Engineering Equipped with latest Software

- For 3D Modeling (UGNX)

- For Equipment layout modeling clash check (PDMS)

- For Thermal calculations & PG Test (In house developed Software)

- For FEA (Finite element analysis) - ANSYS

- Servicing & calibration of Governing system of following turbines

- 30 MW thermal turbine

- 195 MW to 250 MW Siemens design thermal turbine

- 236 MW nuclear Turbines

- RLA of Steam turbines up to 500 MW rating

MANUFACTURING AND TESTING FACILITIES

CNC FLAME CUTTING MACHINE

- For cutting steel plates accurately

- Thickness - 5 mm to 356 mm

- Working Area- 4 m x 13 m

- Three cutting torches

- Facility for cutting & chamfering together

INNOCENTI NC BORING MACHINE

- Double column horizontal boring m/c

- Vertical traverse - 10m & 6 m

- Capable of machining in vertical axis

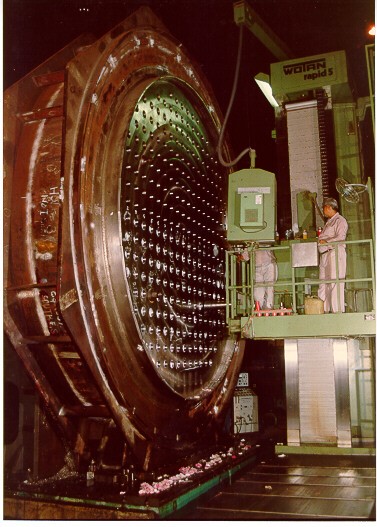

WOTON CNC HORIZONTAL BORER

- Head mounted on bed 8 m long

- Vertical Traverse - 3.5 m

- Capable of machining in vertical axis

CNC LATHE MACHINE

- Make - SAFOP, ITALY

- Swing over bed - 3 mtr

- Admit between centres - 12 mtrs

- Special features - Diamond roller/grinding attachment

CNC VERTICAL TURNING & MILLING MACHINE

- Make- Pietro Carnaughi, ITALY

- Table Dia - 8 m

- Max. Turning Dia - 12m

- Height under bridge - 4 m

- Max. table capacity – 250 ton

5 AXIS CNC HORIZONTAL BORING MACHINE

- Make - PAMA, ITALY

- Spindle - 160 mm

- Spindle travel - 2mtr

- X axis travel - 9 mtr

- Y axis travel - 5mtr

- Rotary table size - 2.5mtr*3mtr

- Special feature - 5 axis simultaneous movement

CNC HORIZONTAL BORING MACHINE

- Make - PAMA, ITALY

- Spindle - 200 mm

- Spindle travel - 3 mtr

- X axis travel - 15 mtr

- Y axis travel - 5.5mtr

- Rotary table size - 4mtr*4mtr

- Rotary table capacity - 100 ton

- Automatic tool changer (atc) - 60 tools

TESTING FACILITIES (STEAM TURBINE SHOP)

-

Laser Alignment Setup for Alignment of LP Diaphragms with LP Inner Casings – 700 MW Nuclear Turbine

Laser alignment facility approved by GE and NPCIL

Laser alignment facility approved by GE and NPCIL - LP Valve Governing test bed (Pressure=120 bars) for 700 MW Nuclear Governing assembly ( Computerized test set up for Functional testing of Butterfly type LP Interceptor and Moderation valves with LP Servomotors – This test set up exists in India only in BHEL Bhopal for 700 MW GE Design Nuclear Turbine )

LP Valve Governing test bed

LP Valve Governing test bed - Shot Peening Facility for shot peening to be carried out in site for last stage LP Blades

- Moment balancing and Sequencing of free standing moving blades.

- LP governing test bed (Pressure=32 bars) for 236 MW Nuclear and up to 250 MW Thermal governing assemblies.

- Hydro testing facility of 700 MW HP Casing.(Hydro Testing using differential pressure arrangement in steps)

SPECIALIZATION IN CONTROLS AND INSTRUMENTATION (C&I) OF STEAM TURBINE EQUIPMENTS FOR THERMAL / NUCLEAR POWER

- Providing comprehensive solutions for the complete power project.

- Design, Engineering, Procurement and supply of Instrumentation items for Turbine, Condenser, MSR and Associated Tanks.

- Detailed Engineering, Field Engineering, Erection, Testing, Calibration, Loop Checking and Commissioning of Control & Instrumentation Systems.

- Providing solutions with Spares/ technical upgrade for existing power plants. Some recent projects executed are Electronic Over speed & trip system for 30MW Bhilai. Condenser tube fouling system for 700 MW KAPP and RAPP project.